Products

PIC MODULES PRODUCTS

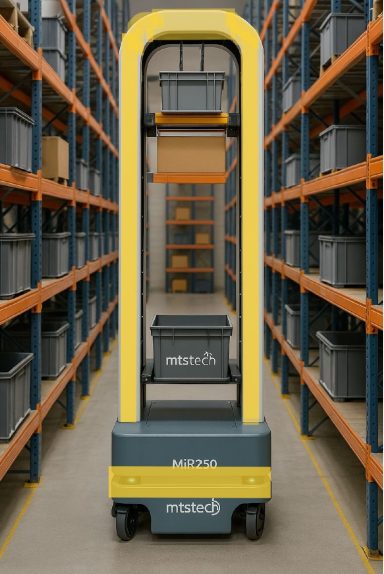

Upper structures for AMRs (Autonomous Mobile Robots)

Top Modules for AMRs. PIC MODULES top modules, Cart, Rack and Dockings are compatible with the most popular brands of AMR in the market.

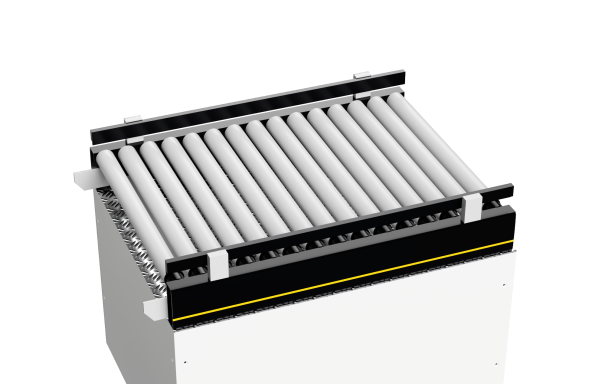

- PIC Roller Modules

- PIC Carts Modules

- PIC Rack Modules

- PIC Lifter Modules

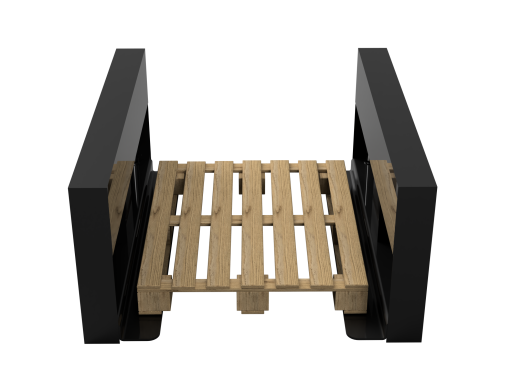

- PIC Cart

- PIC Rack

- PIC Docking Stations

- PIC Accessories

How we work

What to consider

Designing a mobile robot rack involves considering several factors to ensure the robots can be stored, maintained, and monitored efficiently. Below are some key aspects:

1. Rack Purpose:

Transportation of products in various formats using AMRs as rack tractors.

2. Design Considerations:

- Size and Dimensions: The rack must fit the dimensions of the robots, allowing sufficient space for maneuverability and accessibility.

- Weight Capacity: Ensure the rack can support the required weight. Consider the materials used and structural integrity.

- Accessibility: The design should allow easy access to each robot for quick setup or retrieval.

- Mobility: If necessary, design the rack to be mobile, with casters or swivel casters for easy transport.

3. Charging Solutions:

- Power Supply: Include power outlets for charging the robots. Consider using quick-connect charging stations.

- Cable Management: Design to prevent tangling and damage to charging cables.

4. Material Selection:

- Durability: Use materials that can withstand the wear and tear of daily use (steel, aluminum, or heavy-duty plastics).

- Weight: Lightweight materials can be advantageous for mobility, but make sure they remain durable.

5. Safety Features:

- Stability: Ensure the stand is stable and won't tip over when placing or removing robots.

- Secure Anchoring: Design mechanisms to keep robots securely in place, preventing accidental movement or falls.

6. Customization:

- Modular Design: Consider a modular design that can be adjusted or expanded based on the number of robots or changing needs. - Add-ons: Shelves or compartments for tools, manuals, and spare parts.

7. Technology Integration:

- Monitoring Systems: Include built-in displays or Wi-Fi to monitor the status and battery level of each robot.

- Data Docking: Allows data transfer or software updates for robots while docked in the rack.

8. Environment:

- Indoor vs. Outdoor: Ensure the material and design can withstand the elements if used outdoors (waterproofing, UV resistance).

- Temperature Control: If necessary, consider climate control features for sensitive robotic equipment.

9. Aesthetic Design:

- A visually appealing design can enhance the workspace. Consider branding elements if the rack will be visible to customers or stakeholders.

Design Examples:

- Vertical Rack: For stacking multiple robots, useful in limited spaces.

- Mobile Cart: For easily transporting robots between locations. Wall Rack: To reduce the footprint while maintaining robot accessibility.

Summary:

Creating an effective mobile robot rack depends on several specific requirements related to storage, maintenance, load capacity, and even aesthetic considerations. It is essential to consider functional needs, as well as safety and ease of use, when designing the shelf.

©Copyright. All rights reserved. 2025

Necesitamos su consentimiento para cargar las traducciones

Utilizamos un servicio de terceros para traducir el contenido del sitio web que puede recopilar datos sobre su actividad. Por favor revise los detalles en la política de privacidad y acepte el servicio para ver las traducciones.